PLC is a registered trade mark of

Allen-Bradley

for decades since the first PLC in the world.

It

is a classic American story. Two brothers with a knack for invention and business, but no money. Another, older man who knew talent when he saw it and wash willing to invest in that talent. Hard work, luck and inventive genius combined to build a global company. The partnership between

Dr.Stanton Allen and

Lynde and

Harry Bradley resulted in an industrial giant that continues to provide some of the basic tools keep industry humming. The growth from a two-man operation in rented space in someone's factory to a global industrial giant is the

story of an entire century.

History

The company was founded in 1903 as the Compression Rheostat Company by

Dr. Stanton Allen and

Lynde Bradley with an initial investment of $1,000.

In 1910 the firm was renamed Allen-Bradley Company; for close to the next century it provided the bulk of discrete resistors used for electronics

and other products. In 1952 it opened a subsidiary in Galt, Ontario, Canada, that employs over 1000 people. In 1985 a company record was set as

the fiscal year ended with $1 billion in sales. In February 1985, Rockwell International purchased Allen-Bradley for $1.651 billion, which is the

largest acquisition in Wisconsin history.[1]

For all intents and purposes, Allen-Bradley took over Rockwell's industrial automation division.

Rockwell eventually moved its headquarters to Milwaukee. In 2002, when Rockwell split into two companies, Allen-Bradley followed the automation

division into Rockwell Automation.

Now a day, every day you face a new challenge. On the plant floor, it’s producing consistent quality

faster. Reducing parts inventories. Spending less time on training and less money on maintenance. On the top floor, it’s faster time

to market. More flexible production. Zero defects.

Rockwell Automation Integrated Architecture provides seamless integration of control and communication across multiple platforms – process,

motion, drives, and sequential – throughout your facility. We offer Logix Platforms and I/O systems for control, Kinetix for integrated motion,

NetLinx Open Network Architecture for communications, and ViewAnyWare™ for visualization. Our PLC-5®, SLC™ 500, ControlLogix®, CompactLogix ™

and MicroLogix™ Controller , along with a wide range of world-class control components, make your operation and a model of pure efficiency –

shop floor to top floor – while our FactoryTalk® technologies reduce your development time and improve your plant uptime.

Large Control Systems

Our Large Control Systems fit your most demanding application needs. They offer modular architectures and a range of I/O and network options.

These powerful control solutions deliver world-class capabilities from process to safety to motion. Designed for distributed or supervisory

control applications, our large programmable automation controllers (PACs) provide exceptional reliability and performance.

ControlLogix Control Systems >>

Our ControlLogix® control systems use a common control engine with a common development environment to provide high

performance in an easy-to-use environment. Tight integration between the programming software, controller, and I/O modules reduces development

time and cost at commissioning and during normal operation. You can perform standard and safety control in the same chassis for a truly integrated

system. Leverage the high-availability and extreme environment capabilities to meet your application needs.

Small Control Systems

The perfect solution for your mid-range applications, our small controllers offer the features and flexibility you need

without the overhead of larger systems. Choose from standard and safety-certified controllers in chassis-based, packaged and modular designs.

Typical applications include complex machine control, batch processing and building automation.

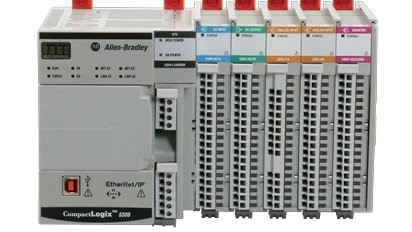

CompactLogix Control Systems >>

Our CompactLogix™ and Compact GuardLogix®

controllers use a common control engine with a common development environment

to provide mid-range application control in an easy-to-use environment. Tight integration between the programming software, controller and I/O

modules reduces development time and cost at commissioning and during normal operation. This commonality provides cost-effective integration of

a machine or safety application into a plant-wide control system because it integrates safety, motion, discrete and drive capabilities in a single

controller.

Micro & Nano Control Systems

Our micro and nano PLCs provide economical solutions to basic control needs for your simple machines ranging from relay

replacement to simple control timing and logic. Compact packaging, integrated I/O and communication, and ease of use make these controllers an

ideal choice for applications such as conveyor automation, security systems, and building and parking lot lighting.

Micro800 Control Systems >>

Our Micro800™ Control Systems are easy to install and maintain.

One software package applies to the entire family. These systems offer just enough control for your lower-cost, stand-alone machines.

You can buy only the functionality you need, and use plug-in modules to personalize your system for specific application needs.

MicroLogix Control Systems >>

For a proven, small programmable logic controller solution, look to our MicroLogix™

family. The MicroLogix 1200

controllers provides features and options to handle extensive range of applications. The MicroLogix 1100

and 1400 controllers increase

the application coverage with enhanced network communications at an affordable price.

Human machine interface

Visualization and HMI solutions help you address your productivity, innovation, and globalization needs.

Our portfolio provides a consistent look and feel for electronic operator interface terminals, distributed client/server HMI, and information

software. Programming tools and advanced software applications include remote access and data analysis to accelerate development and improve

efficiency.

GRAPHIC TERMINALS >>

Our rugged electronic interface solutions are available in a variety of sizes, operator input methods, memory options,

and configurations.

Offers hardware, software, and communications options

Includes ratings for high shock, vibration, and temperature applications

HMI SOFTWARE >>

FactoryTalk® View provides robust functionality in one software HMI solution

Scales from a standalone, machine-level HMI to a distributed visualization solution

Delivers critical visibility on demand and improves productivity at every level of your organization

THIN CLIENTS MANAGEMENT SOFTWARE >>

Customize the user-visualization experience at every terminal when you leverage ThinManager®

technology to create composite applications. Use ThinManager Relevance® technology to centrally manage delivery of HMI applications and other

visual content based on the role of a user and/or the location of a terminal, including thin clients and mobile devices.

Drive System

Our Allen-Bradley® PowerFlex® variable frequency drives and

Kinetix® servo drives offer

solutions from simple machine control, high-speed positioning to demanding medium voltage control. These flexible portfolios

deliver solutions to keep you connected to your operations and help you to be more productive.

ARCHITECTURE DRIVES >>

PowerFlex® 700 Series Architecture-class AC Drives deliver cost-effective solutions

for a wide range of global applications. Designed for ease of use, this general-purpose class of drives provides

time-saving benefits as well as a compact package to optimize panel space and application versatility.

COMPACT DRIVES >>

PowerFlex® 500 Series Compact-class AC Drives deliver a simple

and cost-effective solution for standalone machine level control applications or simple system integration. Designed for ease of use,

this general-purpose class of drives provides a compact package to optimize panel space and application versatility.

SERVO DRIVES >>

Looking for a simpler way to improve performance? Our solutions are designed to simplify machine design,

provide more system flexibility, and improve overall performance. Allen-Bradley Kinetix®

servo drives fit seamlessly into the Logix platform for easy configurability, system integration, and your choice of network

and safety options.